Absorption Costing Definition Example

Then, there is an adjustment for any over and under absorption of fixed overheads. Another drawback of marginal costing is that it considers fixed costs in full for the complete production period. Variable costs of production include direct material, direct labor, and direct equipment costs.

Absorption costing vs. variable costing

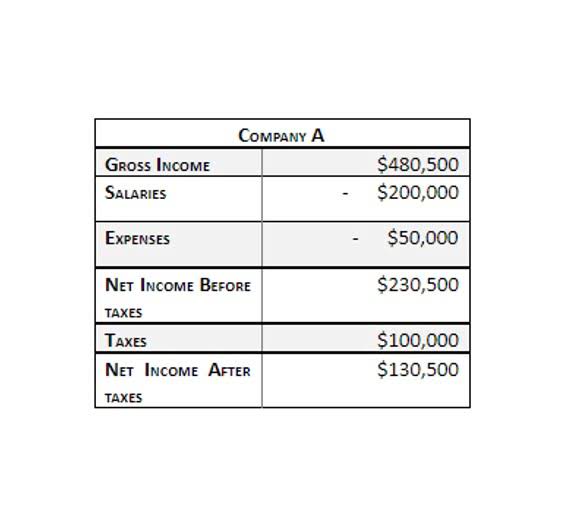

- To support our conclusion and facilitate the decision-making process of the management, we can present the following summary to showcase the effect on the income statement of the company.

- Absorption costing is a system used in valuing inventory, which considers the cost of materials and labor, and also the variable and fixed manufacturing overheads.

- However, managers must be careful when interpreting the total costs as closing inventory may be overvalued in some cases.

- Costs are separated as variable and fixed (cost behavior) which is helpful for internal analysis.

- Managing absorption costing can be complex due to the need to track both direct costs and indirect costs.

- Variable or marginal costing and full or absorption costing methods are two widely used inventory costing methods.

It’s all about capturing the full picture – every penny spent needs to be accounted for on their spreadsheets so they can report accurate valuations on their stock valuation. In the bustling world of manufacturing, time is money and precision is key. Imagine a company in this sector that specialises in creating high-quality apparel, namely scarves and dresses. I am a finance professional with 10+ years of experience in audit, controlling, reporting, financial analysis and modeling.

What Is Absorption Costing?

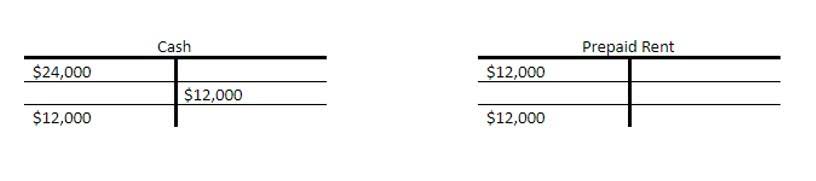

Let’s walk through a practical example to illustrate overhead absorption in action. The company has budgeted factory overheads of $240,000 for the year and expects to use 12,000 machine hours. Absorption costing is a simple and comprehensive approach for a production facility with a small number of products.

Modern Approaches and Technology

The choice between absorption costing and variable costing depends on the nature of the business, the stability of inventory levels, and the desired level of cost control and decision-making accuracy. One of the key differences between absorption costing and standard costing is how costs are allocated to products. In absorption costing, all manufacturing costs, including direct materials, direct labor, and both variable and fixed overhead costs, are allocated to the cost of goods sold. This means that fixed overhead costs are included in the cost of each unit produced. On the other hand, standard costing only allocates predetermined costs to products based on standard rates and quantities. By including both direct and indirect costs, absorption costing provides a comprehensive view of the total cost of a product.

By also calculating the price per unit in the suggested contract, we can compare it to the Absorption Cost. We notice that the amount offered will not even cover the cost of the products. We have to either negotiate a higher contract price or look into possible cost optimizations. The sales director has informed us that they have received a quote to provide 12,000 pcs of a ski pant model, for a total contract price of 600,000 euro. As part of the financial team, the sales department asked us if this contract will be profitable for the company. With the process of primary apportionment or distribution, the loading of overheads for all the departments i.e. production as well as service departments can be obtained.

In summary, overhead absorption plays a vital role in cost accounting and financial decision-making, supporting businesses in achieving long-term sustainability and unearned revenue profitability. The overall difference between absorption costing and variable costing concerns how each accounts for fixed manufacturing overhead costs. Absorption costing is a costing method that includes all direct costs of production including variable costs and fixed overhead costs.

- The company has budgeted factory overheads of $240,000 for the year and expects to use 12,000 machine hours.

- The main aim is to ensure that all manufacturing costs are absorbed by the products produced, making it easier for businesses to track profitability, set prices, and evaluate cost efficiency.

- By using absorption costing, the company ensures these costs are distributed across all tables produced, giving a clearer picture of the total production cost and helping to set competitive yet profitable prices.

- If the amount of overhead assigned to the products manufactured is greater than the amount of overhead actually incurred, the products have overabsorbed the overhead costs.

- Implementing absorption costing poses several challenges that businesses should consider.

Variable costing results in gross profit that will be slightly higher, resulting in a slightly higher gross profit margin compared to absorption costing. In other words, under absorption costing, each unit of goods has a total production cost of just over £4. Many businesses produce similar products in batches that do not require customization. Although these trends are diminishing, however, absorption costing is a suitable method for such production facilities.

Definition of Absorption Costing

Effectively managing and reporting these crucial inventory asset values, consistent with external financial reporting standards, often relies on integrated ERP systems. It works by totaling all the manufacturing costs for a period and dividing that sum by the total number of units manufactured during that same time frame. These costs represent the essential infrastructure, equipment, and core personnel required to keep the factory operational, regardless of the specific number of units produced day-to-day. Be aware of “mixed costs” (like some utilities) with fixed and variable components; accurately separating these parts improves costing precision. Absorption costing includes all manufacturing costs in the value of your inventory.

- It includes direct materials, direct labor, fixed manufacturing overhead, and variable manufacturing overhead, providing a full picture of production costs.

- Another drawback of the full costing method is that it may hide fixed costs from the income statement.

- In many ways, this is a more accurate way to account for the true cost of producing the products.

- This method provides a more complete view of total production costs, which is valuable for external stakeholders.

- Understanding how to effectively manage production costs is a common challenge for directors in any sector.

- A company may also have to use absorption costing which is GAAP-compliant if it uses variable costing.

Absorption costing is a method of costing that includes all direct and indirect production costs in the cost of goods sold. By accurately calculating the absorption cost per unit, businesses can set prices that reflect the true cost of production. This ensures that products are priced competitively while also covering the total costs involved in their production. While absorption costing provides a comprehensive view of production costs, variable costing can be absorption costing formula more useful for certain managerial decisions. Variable costing highlights the contribution margin—the difference between sales revenue and variable costs—making it easier to analyze profitability for specific products or segments.

Absorption costing improves the accuracy of your accounts for ending inventory, as expenses are linked to the total cost of your inventory on hand. Moreover, further expenses are assigned to unsold products, which means that the actual amount of expenses reported on your income statement may end up being reduced, providing a higher net income. By shifting some production costs from the income Bookkeeping for Startups statement to the balance sheet as inventory, a company may lower its overall costs and thus increase net income. At the same time, accurate absorption costing boosts the value of inventory by valuing it at full production cost. Unlike the marginal costing method, absorption costing allocates full costs of production to the per unit analysis.

Leave a Reply